Exploring the Features and Applications of the Best CNC Milling Machines for Every Industry

In recent years, the global CNC milling machine market has witnessed significant growth, propelled by advancements in technology and a surge in demand across various industries. According to a 2021 report by MarketsandMarkets, the CNC milling machine market is projected to reach $100 billion by 2026, with Asia-Pacific being the fastest-growing region, primarily due to the rise of China's manufacturing capabilities.

As a representative of excellence in manufacturing, China has emerged as a leader in exporting CNC milling machines, illustrating its robust industrial framework and innovation-driven approach. The versatility of CNC milling machines allows them to cater to diverse sectors, from automotive and aerospace to healthcare and electronics, thus revolutionizing production processes and enhancing precision.

This blog will explore the key features and applications of the best CNC milling machines, highlighting how they can optimize operations across different industries.

As a representative of excellence in manufacturing, China has emerged as a leader in exporting CNC milling machines, illustrating its robust industrial framework and innovation-driven approach. The versatility of CNC milling machines allows them to cater to diverse sectors, from automotive and aerospace to healthcare and electronics, thus revolutionizing production processes and enhancing precision.

This blog will explore the key features and applications of the best CNC milling machines, highlighting how they can optimize operations across different industries.

Key Innovations in CNC Milling Machines Shaping 2025 Industry Trends

The landscape of CNC milling machines is rapidly evolving, with key innovations anticipated to shape industry trends by 2025. One significant advancement is the integration of artificial intelligence, which is increasingly driving market transformation. This technology allows for enhanced precision and efficiency in multi-axis machining centers, resulting in a significant boost in production capabilities across various sectors. The growing demand for high-precision components is propelling the CNC machine tools market, with projections estimating an increase of USD 21.9 billion from 2025 to 2029.

Moreover, the CNC machinery market is experiencing substantial growth, expected to rise from USD 110.65 billion in 2024 to USD 182.34 billion by 2034. This surge is largely attributed to the industry's shift towards automation and smart manufacturing practices, making CNC machines more versatile and capable of meeting the evolving demands of manufacturing. As companies seek to enhance productivity and maintain competitive advantages, investing in advanced CNC milling technologies will become a critical strategy for success in the coming years.

Key Innovations in CNC Milling Machines Shaping 2025 Industry Trends

Essential Features of High-Performance CNC Milling Machines for Diverse Applications

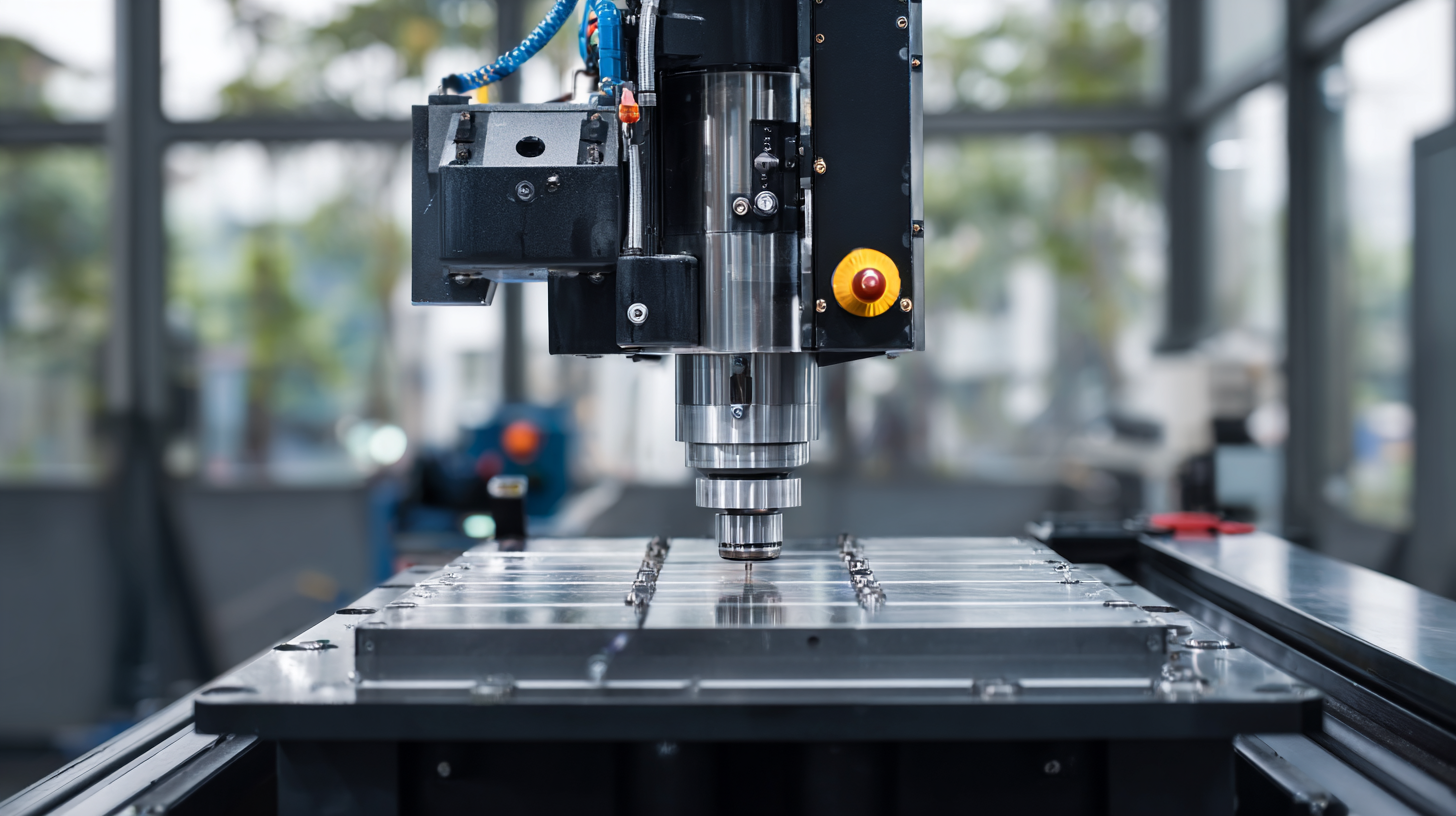

When it comes to high-performance CNC milling machines, several essential features define their effectiveness across various industries. Robust construction and high-quality materials are fundamental for ensuring durability and precision in machining. These machines are engineered to withstand the rigors of continuous operation while maintaining accuracy in complex tasks. Additionally, advanced spindle technology contributes to improved speed and torque, allowing for faster cycle times and enhanced production capabilities.

Another critical feature is the integration of sophisticated control systems that enable intuitive programming and operation. User-friendly interfaces, often paired with advanced simulation software, facilitate easy adjustments and help minimize setup times. Furthermore, the adaptability of CNC milling machines to process a wide range of materials—from metals to plastics—makes them indispensable in fields such as aerospace, automotive, and fabrication. This versatility, combined with the ability to execute intricate designs with high repeatability, positions CNC milling machines as vital equipment for companies aiming to innovate and meet the increasing demands of their respective industries.

Checklist for Selecting the Right CNC Milling Machine for Your Industry Needs

Selecting the right CNC milling machine is crucial for optimizing production, and there are several essential features to consider based on the specific needs of your industry. First, assess the machine's precision and repeatability, as these factors significantly influence the final product quality. Additionally, consider the machine's versatility, especially if your projects require different materials or intricate designs. Some CNC mills offer advanced capabilities such as multi-axis machining, which enables more complex geometries that can be beneficial across various sectors, including aerospace and automotive.

Another important aspect is the integration of modern technology, such as software tools that facilitate tool selection and assembly building. The latest advancements in CNC technology allow for seamless integration with design software, enhancing productivity by streamlining the planning process. Furthermore, evaluate the support and service options available, as reliable customer service can greatly reduce downtime.

When choosing a CNC milling machine, it’s essential to create a tailored checklist that considers your operational workflow, production volume, and specific application needs to ensure you make a well-informed decision.

Real-World Applications: How CNC Milling Machines Transform Manufacturing Processes

CNC milling machines have revolutionized manufacturing processes across various industries by enhancing precision and efficiency. In sectors like aerospace and automotive, these machines are essential for producing intricate components that meet stringent safety standards. The ability to automate complex cutting tasks allows manufacturers to achieve high repeatability, minimizing human error and ensuring that every part is crafted to exact specifications. This level of precision is crucial when dealing with parts that must fit seamlessly within larger systems, as any deviation can compromise performance and safety.

In the medical field, CNC milling machines are instrumental in creating customized implants and surgical instruments tailored to individual patient needs. The technology allows for rapid prototyping and iterative design, enabling medical professionals to quickly adapt to the evolving requirements of their practice. Additionally, in the electronics industry, CNC milling aids in the production of circuit boards and housing units, where precision is paramount. With their versatility and capability to handle a variety of materials, CNC milling machines not only streamline the production process but also open up new possibilities for innovation, ultimately transforming traditional manufacturing into a more agile and responsive operation.

Future-Proofing Your Operations: Adapting CNC Milling Technology for Industry 2025

As we approach Industry 2025, the need for future-proofing operations has never been more crucial, particularly in the realm of CNC milling technology. According to a report by Market Research Future, the global CNC machine market is expected to reach $100 billion by 2025, driven by advancements in automation and smart manufacturing. Companies must adapt their CNC milling processes to integrate these technologies, ensuring efficiency and competitiveness in a rapidly changing landscape.

To successfully transition into this new era, businesses should consider investing in CNC systems that offer adaptability. Machines equipped with IoT capabilities can provide real-time data and predictive maintenance, reducing downtime by up to 30%, as reported by Deloitte. This not only enhances productivity but also extends the lifespan of machinery, making it a strategic investment for the future.

**Tip:** When selecting a CNC milling machine, prioritize those with modular designs that allow for upgrades. This way, your equipment can evolve alongside technological advancements without requiring a complete overhaul. **Tip:** Regular training for your operators on new technologies can significantly impact productivity—companies that invest in this area see an average productivity increase of 20%.

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: [email protected]

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information