Discover the Finest Portable CNC Machines from China's Leading Manufacturers

In the realm of modern manufacturing, the demand for portable CNC machines has surged, reflecting a 25% annual growth rate in the global CNC market, as noted by recent industry reports. These versatile tools are revolutionizing the way businesses approach fabrication and assembly, offering unmatched precision and convenience, especially for small to medium-sized enterprises.

With China's prominence as a leading manufacturer of portable CNC machines, it is crucial to discern which brands deliver exceptional quality and value. As the industry continues to evolve, understanding the key features and specifications of these machines becomes imperative for companies aiming to enhance their operational efficiency.

This blog aims to provide insights into identifying high-quality manufacturers and offers comparisons that will help businesses make informed purchasing decisions in a competitive landscape.

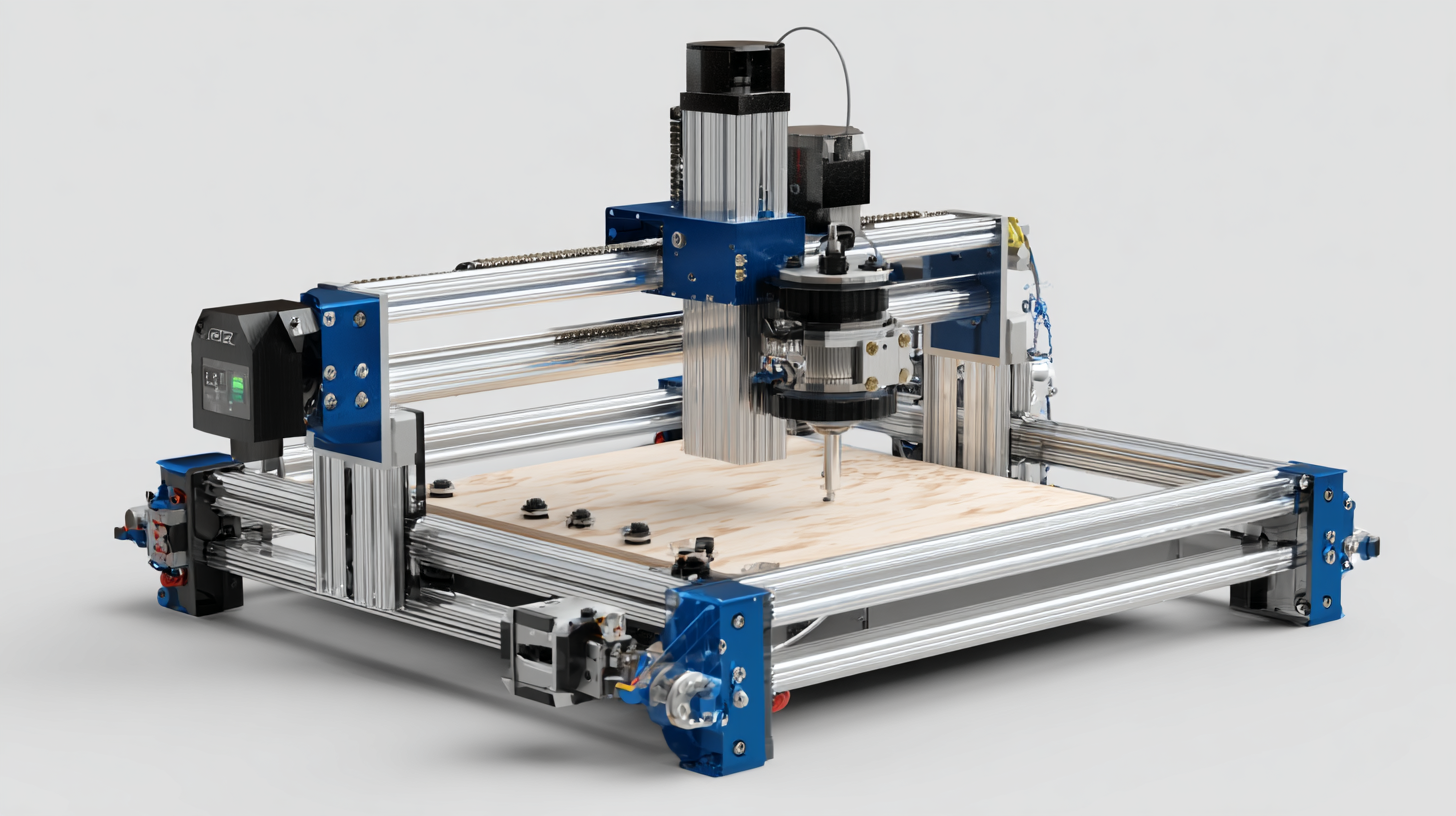

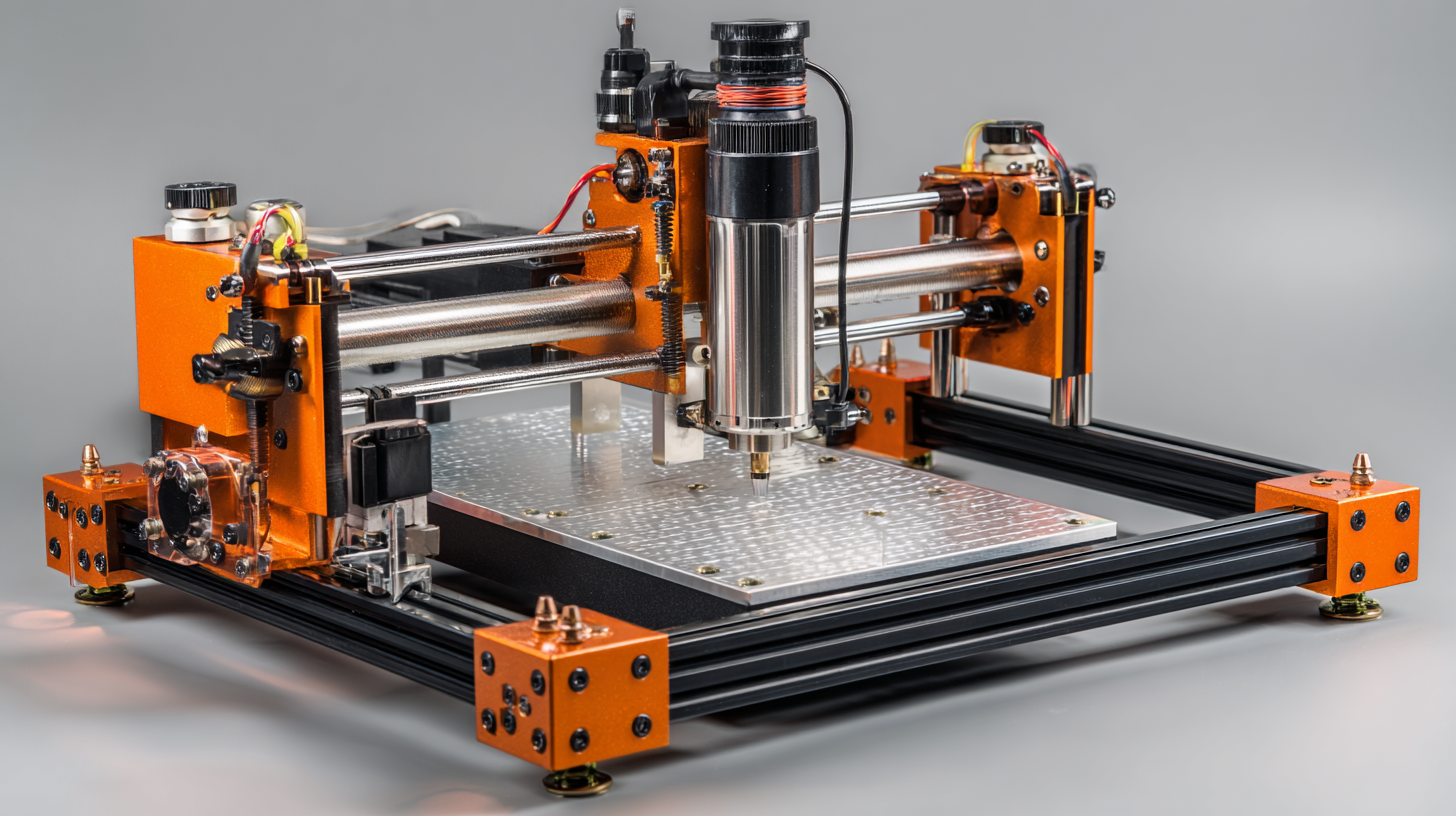

Understanding CNC Machines: Key Features and Benefits of Portability

The rise of portable CNC machines signifies a transformative shift in modern manufacturing. These compact systems combine precision, versatility, and efficiency, making them essential for businesses seeking to optimize their operations. According to industry reports, the portable CNC machine market is projected to grow at a CAGR of 5.6% through 2028, driven by advancements in technology and an increasing need for on-site machining capabilities. Portability enables manufacturers to reduce setup times and transportation costs while enhancing productivity on the shop floor.

When considering the benefits of portable CNC machines, key features include ease of transport, user-friendly interfaces, and a range of compatible tooling options. These machines can be easily moved to different work sites, allowing for flexibility in production processes. A recent review highlighted that machines designed for portability often pack similar power and efficiency as their larger counterparts, making them ideal for companies needing supplementary capacity.

**Tips:**

1. Evaluate your specific needs: Before purchasing, assess the scope of your projects to understand the size and capabilities required in a portable CNC machine.

2. Consider integration: Ensure the portable machine can easily integrate with your existing equipment to maximize efficiency.

3. Look for training opportunities: Many manufacturers offer training sessions to help you get the most out of your new equipment, enhancing skills and productivity.

Identifying Top Manufacturers: Key Credentials to Look For

When searching for the finest portable CNC machines from China's leading manufacturers, it’s crucial to identify key credentials that signify quality and reliability. First and foremost, reputation plays a pivotal role. Established manufacturers often have a proven track record of delivering high-performance machines and excellent customer service. Look for companies that have garnered positive reviews and testimonials, as this indicates their reliability in both product performance and post-purchase support.

Another essential credential to consider is the certification and compliance of the manufacturers. Reliable CNC machine manufacturers will hold certifications such as ISO 9001, which demonstrates their commitment to quality management systems. Additionally, check for compliance with international safety and performance standards, which not only ensures longevity but also safeguards against potential hazards during operation. By focusing on these key credentials, buyers can confidently navigate the competitive landscape of portable CNC machines and select a manufacturer that meets their specific needs.

Top Portable CNC Machines by Cutting Speed

This chart illustrates the cutting speed of various portable CNC machines, showcasing their performance capabilities.

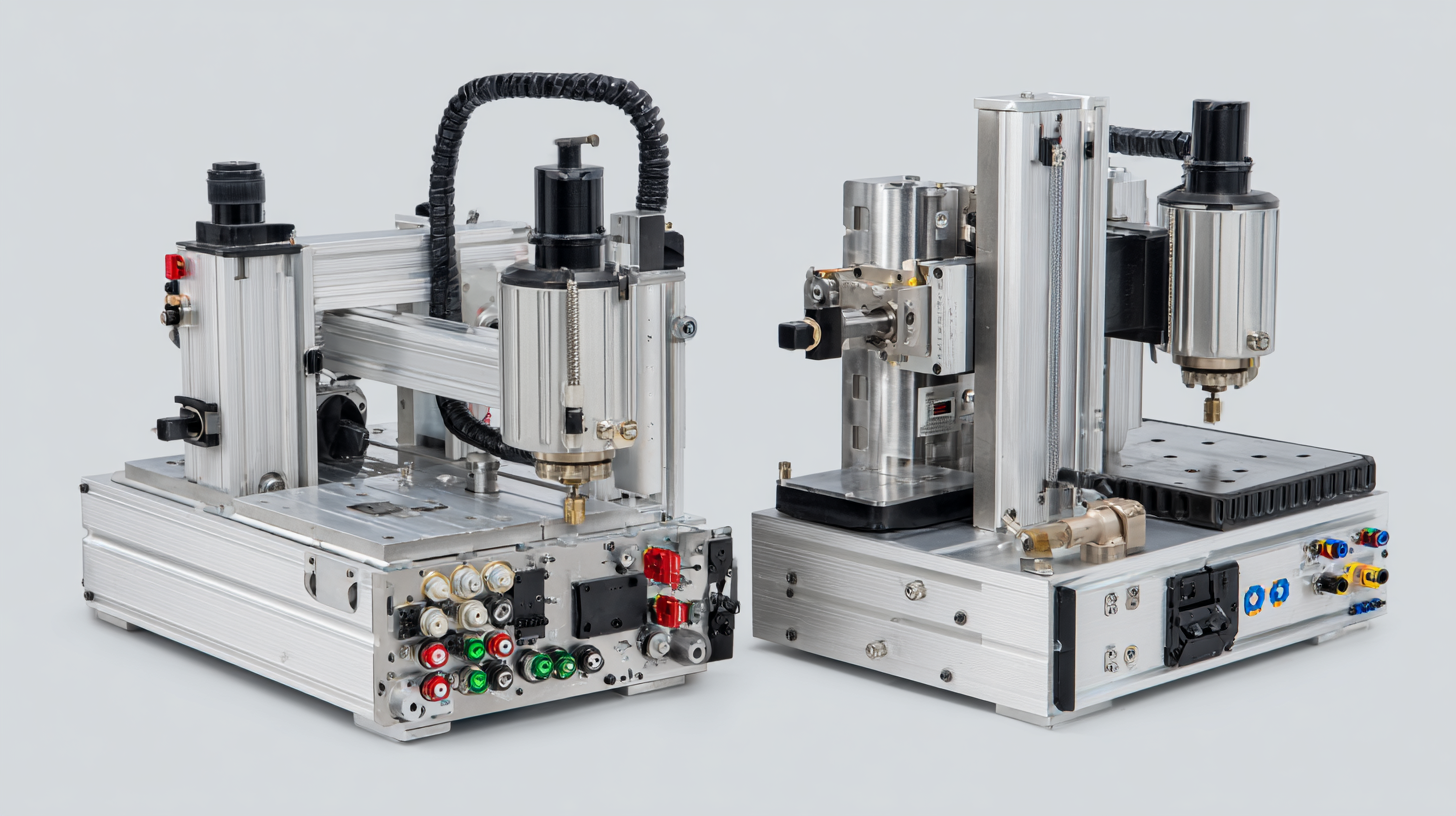

Evaluating Quality: Key Performance Metrics for CNC Machines

When evaluating the quality of portable CNC machines, several key performance metrics are crucial for determining their efficiency and effectiveness in manufacturing processes. Recent industry studies highlight that accuracy and precision are among the primary metrics; CNC machines must maintain tolerances within ±0.01 mm to effectively compete in high-precision applications. Additionally, the integration of advanced monitoring systems, such as integrated force sensors in motor spindles, has proven to enhance operational performance by providing real-time feedback on force exerted during machining, allowing for timely adjustments and reduced errors.

Energy efficiency also plays a significant role in assessing the performance of CNC machines. Reports indicate that machines specifically designed for energy management can reduce energy consumption by up to 20% through innovative power management strategies. By implementing key performance indicators (KPIs) related to energy usage, manufacturers can not only lower operational costs but also contribute to more sustainable production practices. Incorporating these metrics during the procurement process can ensure that the selected CNC machines are not only capable of delivering high-quality results but also supporting long-term efficiency goals.

Navigating Supply Chains: Tips for Sourcing from Chinese Factories

Navigating supply chains when sourcing portable CNC machines from Chinese manufacturers requires an understanding of several critical factors. According to the "Global CNC Machine Tools Market Report" by Mordor Intelligence, the CNC machine market is projected to reach $100 billion by 2025, with a significant portion attributed to Asia, particularly China. This rapid growth highlights the importance of establishing strong connections with reliable manufacturers to ensure quality and efficiency.

When dealing with Chinese suppliers, it is essential to conduct comprehensive background checks and verify certifications. A survey by Statista shows that over 80% of businesses claim that quality assurance is their top priority when selecting a manufacturer. Engaging with suppliers that have established quality management systems, like ISO 9001, enables buyers to mitigate risks associated with poor workmanship or substandard materials. Furthermore, understanding the logistics involved in shipping from China is crucial; a report from Prologis indicates that the average lead time for cross-border shipments can vary from 30 to 90 days depending on the region and shipping method. Implementing efficient supply chain strategies, therefore, is vital to maintaining competitiveness in the rapidly evolving CNC machine market.

Comparing Options: How to Assess Pricing and After-Sales Support

When considering the purchase of a portable CNC machine from China's leading manufacturers, evaluating pricing and after-sales support is crucial. The market is saturated with various options, making it essential to compare not just the initial costs but also the long-term value. While a lower price might seem appealing, it’s important to assess what’s included in that price. Look for transparency regarding additional costs such as shipping, taxes, and any potential hidden fees that could arise after the purchase.

Equally important is the after-sales support offered by the manufacturer. Reliable support can significantly influence your experience with the CNC machine. Examine warranty options, technical assistance, training, and availability of spare parts. Companies that provide comprehensive after-sales service demonstrate their commitment to customer satisfaction and product longevity. By prioritizing these factors, you can make a well-informed decision that balances affordability with quality support, ensuring you get the best value from your investment in portable CNC technology.

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: [email protected]

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information