Understanding Global Manufacturing Standards for Best CNC Milling Processes

In today's highly competitive manufacturing landscape, understanding global manufacturing standards is crucial for achieving excellence in CNC milling processes. As industries continue to evolve, the demand for precision, efficiency, and quality control in production has never been higher.

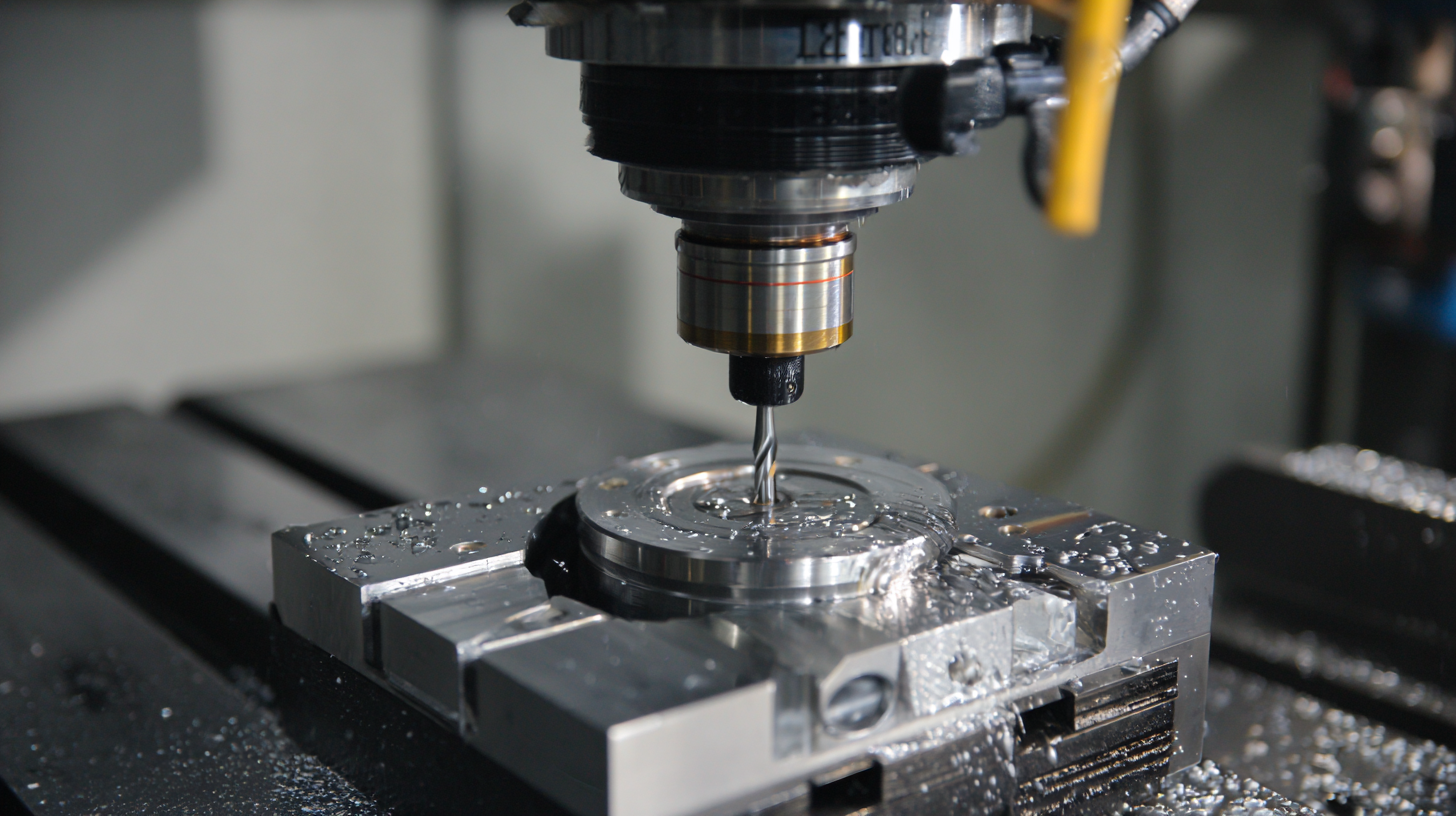

CNC milling, a vital component of modern manufacturing, utilizes computer-controlled machines to create intricate designs with remarkable accuracy. This blog will provide a comprehensive tutorial on the best practices in CNC milling, highlighting the significance of adhering to international standards. By exploring various guidelines and techniques, manufacturers can enhance their operational processes, reduce errors, and ultimately deliver superior products to their clients.

CNC milling, a vital component of modern manufacturing, utilizes computer-controlled machines to create intricate designs with remarkable accuracy. This blog will provide a comprehensive tutorial on the best practices in CNC milling, highlighting the significance of adhering to international standards. By exploring various guidelines and techniques, manufacturers can enhance their operational processes, reduce errors, and ultimately deliver superior products to their clients.

Join us as we delve into the intricacies of CNC milling and discover how to optimize your manufacturing processes to meet global benchmarks.

Benefits of After-Sales Service in CNC Milling: Enhancing Customer Satisfaction and Loyalty

In the competitive landscape of CNC milling, after-sales service plays a pivotal role in enhancing customer satisfaction and fostering loyalty. Providing comprehensive support following the sale not only reassures clients of their investment but also solidifies a long-term relationship. Prompt responses to inquiries, effective troubleshooting, and maintenance services can significantly impact a customer's perception of a brand. This commitment to service excellence encourages repeat business and generates positive word-of-mouth referrals, which are invaluable for sustained growth.

**Tip:** Regular follow-ups post-purchase can help identify potential issues before they escalate. Implementing a customer feedback loop can further refine your service offerings, tailoring them to meet specific needs.

Additionally, training programs for customers post-purchase can empower them to utilize CNC milling machines more effectively. A well-informed user is less likely to face operational challenges, which mitigates frustration and builds trust in the brand. This proactive approach not only showcases a company's dedication to its clients but also enhances the overall usability of their products.

**Tip:** Consider offering virtual training sessions or on-site workshops to help clients maximize their machine's capabilities. Providing this added value reinforces customer loyalty and positions your brand as a trusted industry leader.

Understanding Global Manufacturing Standards for CNC Milling

Evaluating Maintenance Costs: A Breakdown of Expenses in CNC Milling Operations

In the realm of CNC milling operations, understanding maintenance costs is crucial for optimizing productivity and managing budgets effectively. According to a report by T. Jones in the "International Journal of Advanced Manufacturing Technology," approximately 15-25% of total production costs can be attributed to maintenance activities in CNC machining. This statistic underscores the importance of not only implementing efficient milling processes but also securing an effective maintenance strategy to minimize unwanted downtimes and associated expenses.

A detailed breakdown of expenses reveals that scheduled maintenance typically accounts for about 60% of the overall maintenance budget in CNC operations, whereas unplanned repairs can inflate costs significantly, sometimes by as much as 50%, as noted in the "Manufacturing Engineering" magazine. By investing in predictive maintenance technologies, manufacturers can reduce these unexpected costs. For instance, companies that integrate IoT technologies have reported a reduction in maintenance costs by nearly 20%, showcasing how smart investments in technology not only improve production reliability but also enhance cost efficiency in the long run.

Understanding Global Manufacturing Standards: Ensuring Quality and Compliance in CNC Processes

In the world of CNC milling, understanding global manufacturing standards is crucial for ensuring quality and compliance. These standards provide a framework that manufacturers must adhere to in order to maintain consistency and reliability in their processes. Compliance with standards such as ISO 9001 not only enhances operational efficiency but also builds trust with clients and stakeholders who demand high-quality outcomes. By aligning with these regulations, companies are better positioned to minimize errors and rework, ultimately leading to cost savings and improved productivity.

Furthermore, global manufacturing standards facilitate interoperability between different machines and processes, enabling firms to collaborate seamlessly across borders. With varying regulations in different regions, staying abreast of international standards helps manufacturers navigate complex compliance landscapes. This understanding allows companies to implement best practices in their CNC processes, ensuring that they produce components that meet or exceed customer specifications. By prioritizing quality through adherence to established standards, manufacturers can gain a competitive edge in today’s fast-paced industrial environment.

Best Practices for Optimizing CNC Milling Efficiency: Strategies for Cost Reduction and Performance Improvement

Optimizing CNC milling efficiency is essential for reducing costs while improving overall performance. To achieve this, companies must focus on best practices that streamline operations and enhance productivity. One key strategy is to implement a robust preventive maintenance schedule. Regularly servicing equipment ensures that machines operate at peak performance, reducing downtime and extending their lifespan.

Tips: Conducting daily checks on your CNC machines can help identify potential issues early on. Keeping a detailed log of maintenance activities allows for better scheduling and can prevent unexpected failures.

Another vital practice is to invest in advanced tooling and technology. Utilizing high-quality cutting tools and software designed for CNC machining can significantly reduce cycle times and improve surface finishes. Furthermore, exploring new techniques such as high-speed machining or adaptive feed rates can lead to substantial efficiency gains.

Tips: Regularly review and update your tooling inventory to ensure that you're using the best options available. Collaborating with tool suppliers for customized solutions can also lead to performance enhancements tailored to your specific milling needs.

| Process Parameter | Best Practice | Efficiency Impact (%) | Cost Reduction ($) | Performance Improvement (%) |

|---|---|---|---|---|

| Cutting Speed | Optimize RPM based on material | 15 | 200 | 10 |

| Feed Rate | Adjust feed according to part complexity | 20 | 150 | 12 |

| Tool Selection | Use high-quality tooling | 25 | 300 | 15 |

| Cooling and Lubrication | Implement optimal coolant flow | 18 | 100 | 8 |

| Setup Time | Standardize setup procedures | 30 | 250 | 20 |

How to Implement Effective Training Programs for CNC Operators: Bridging Skill Gaps in Precision Manufacturing

Creating effective training programs for CNC operators is essential to bridging skill gaps in the highly competitive field of precision manufacturing. As technology continues to evolve, it is crucial that operators are not only familiar with CNC machinery but also equipped with the latest techniques and best practices. A tailored training program should focus on practical skills, such as tool selection, machine setup, and program optimization, ensuring that operators can efficiently translate engineering designs into high-quality products.

Moreover, integrating hands-on training with theoretical instruction can significantly enhance learning outcomes. Simulation-based training tools provide a risk-free environment for operators to practice and understand machine operations before working on the floor. By fostering a culture of continuous improvement and encouraging feedback, manufacturers can identify specific skill deficits within their teams, leading to targeted training initiatives. Engaging experienced operators as mentors can also facilitate knowledge transfer, ensuring newer employees gain valuable insights into complex machining processes while building a supportive learning environment.

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: [email protected]

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information