Solutions for Optimal CNC Router Kit Performance

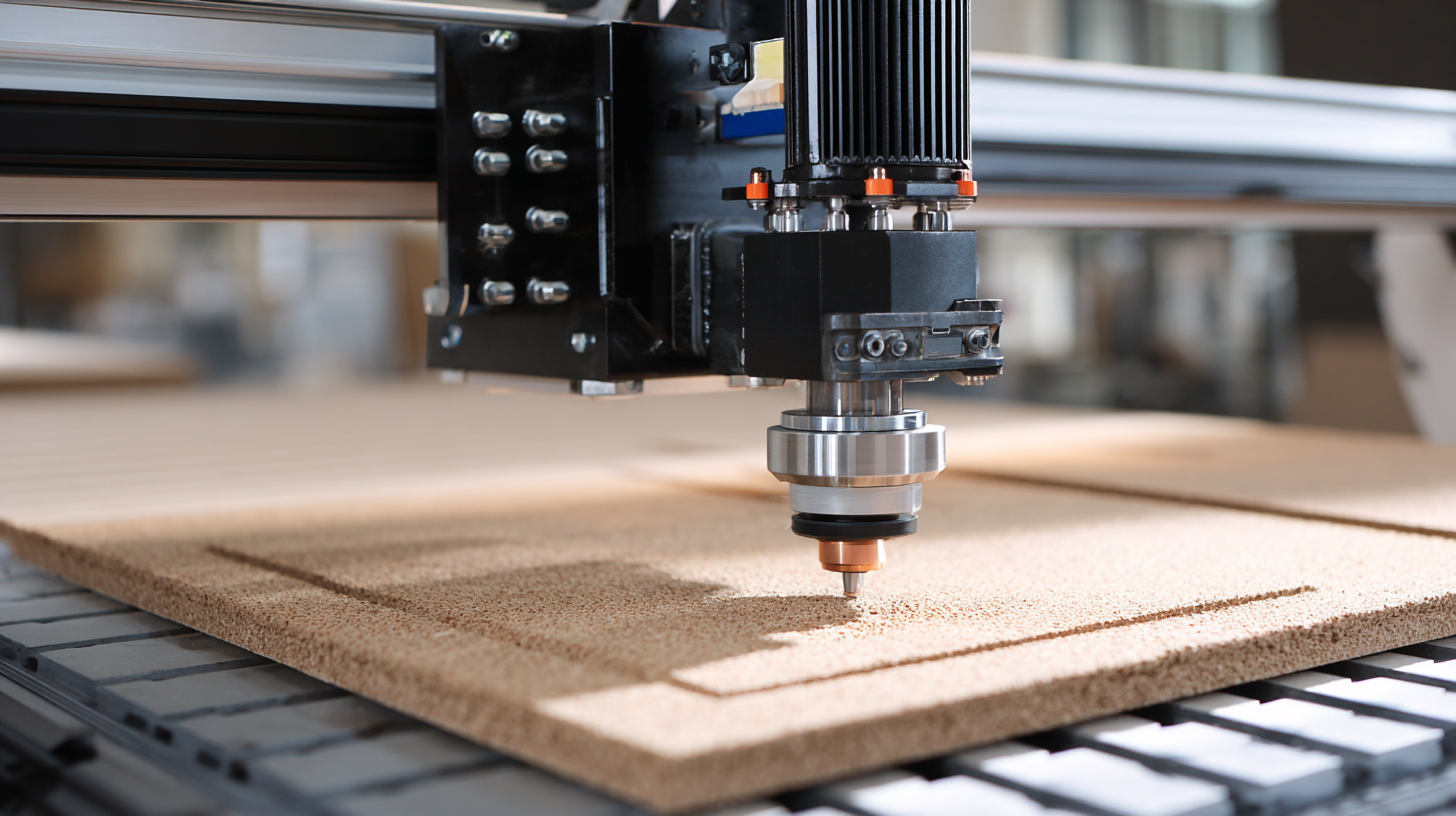

In the world of precision machining and woodworking, the choice of a high-performance CNC router kit can significantly influence the quality and efficiency of your projects. As technology continues to evolve, it is essential for both amateur enthusiasts and professional craftsmen to stay informed about the best options available in the market. This blog delves into solutions for optimal CNC router kit performance, exploring various features that enhance functionality, reliability, and overall output. Whether you are looking to upgrade your current setup or are new to the realm of CNC routing, understanding the integral components and innovative technologies behind these kits will empower you to make informed decisions. Join us as we uncover the essential elements that constitute a top-notch CNC router kit, ensuring that your creative endeavors are met with success and precision.

Best Practices for Achieving High Precision with CNC Router Kits

Achieving high precision with CNC router kits is essential for professionals and hobbyists alike, and there are several best practices to consider. One key factor in precision is the rigidity of the machine. According to a report by the International Journal of Advanced Manufacturing Technology, machines that maintain structural integrity during operation can improve accuracy by up to 20%. This emphasizes the importance of selecting a CNC router kit that features a robust frame and components, which can reduce vibrations and enhance performance, especially when cutting hard materials.

In addition to machine quality, proper calibration and maintenance play a crucial role in ensuring optimal performance. A study by Advanced Materials Research indicated that regular calibration of the CNC system can decrease tool wear and increase dimensional accuracy by as much as 15%. Maintaining sharp, high-quality bits tailored to the material being processed can also significantly impact the outcome, as dull tools can lead to uneven cuts and increased machining time. By adhering to these best practices, users can achieve remarkable precision, ultimately leading to superior finished products.

Optimal CNC Router Kit Performance

This chart illustrates the impact of different optimization techniques on the precision of CNC router kits. Each technique demonstrates a percentage increase in precision, showcasing the importance of best practices.

Exploring Diverse Industry Applications for Enhanced CNC Router Performance

Exploring the diverse applications of CNC routers reveals their critical role in multiple industries, from woodworking to automotive engineering. As the CNC machines market is projected to reach an impressive USD 170.4 billion by 2033, growing at a CAGR of 9.80%, the demand for improved performance becomes even more essential. Companies are increasingly integrating sophisticated technology to enhance precision and repeatability in their machining processes. For instance, CNC routers made from advanced materials like metal composites could offer better stability compared to traditional wooden constructions.

To maximize performance, users should consider the following tips: First, ensure your CNC router is equipped with reliable and up-to-date software, such as GRBL, which is designed for precise control of CNC machines. Second, regularly maintain your equipment and calibrate it to maintain accuracy over time, as even minor misalignments can lead to significant errors in production. Lastly, evaluate your operational needs against available market insights—the CNC router machine market was valued at about USD 691 million in 2023, with a projected growth rate of 3.5% annually. This data can guide businesses in making informed investment decisions in tools that are most aligned with their operational goals.

Data-Driven Insights: The Impact of CNC Router Kits on Manufacturing Efficiency

The advent of CNC router kits has revolutionized manufacturing efficiency across various industries. By leveraging data-driven insights, businesses can better understand how these tools influence productivity and operational workflows. The integration of advanced technology in CNC routers allows for precise cuts and complex designs that were once labor-intensive and time-consuming. As a result, manufacturers can significantly reduce lead times and improve the quality of their outputs.

Moreover, tracking performance metrics in real-time empowers companies to optimize their CNC router kits. Information generated from usage patterns, maintenance needs, and production rates can inform decisions on best practices and equipment upgrades. This reliance on data not only enhances the workflow but also leads to cost savings by minimizing waste and maximizing resource utilization. As manufacturers continue to embrace CNC technology, the transformative effects on their efficiency and output are becoming increasingly evident, driving the industry towards a more productive future.

Essential Maintenance Tips to Maximize CNC Router Kit Lifespan and Performance

To ensure the longevity and optimal performance of a CNC router kit, regular maintenance is crucial. Studies show that routine inspections can decrease machine wear by up to 30%. This involves checking and tightening belts, cleaning dust and debris from the machine, and ensuring lubricants are applied to moving parts. According to the American National Standards Institute (ANSI), proper lubrication can significantly enhance the accuracy of operations, which is essential in achieving high-quality finishes.

Another key aspect of maintenance is calibration. Regularly calibrating your CNC router can improve machining precision by 15% to 25%, as noted in the latest industry reports. This entails adjusting the settings and verifying the alignment of components, which prevents errors in cuts and enhances the overall efficiency of the machine. Additionally, replacing worn-out components promptly ensures that the machine operates at its finest, further avoiding costly downtime. By prioritizing these maintenance practices, users can extend the lifespan of their CNC router kits and sustain peak performance levels, allowing for more productive and profitable operations.

Innovative Techniques for Material Optimization in CNC Router Operations

Innovative Techniques for Material Optimization in CNC Router Operations

In the world of CNC router operations, optimizing material usage is not just a cost-saving measure; it’s essential for achieving high-performance results. According to a recent report by the Association for Manufacturing Technology, optimizing material can lead to a reduction in waste by up to 20%, which significantly impacts production efficiency. One effective technique is the use of nesting software, which intelligently arranges cut patterns to maximize material usage. This software considers the geometry of the pieces being cut, minimizing leftover scrap and ensuring that materials are used to their fullest potential.

Tips: Implementing a regular review of cutting strategies can greatly enhance material optimization. By analyzing previous jobs, operators can identify patterns in waste and make adjustments for future projects. Investing in high-quality, sharp router bits also makes a difference, as precise cuts reduce the likelihood of chipping and breakage, leading to less wasted material.

Another innovative approach involves using advanced CNC technologies such as adaptive feed rate controls. This entails using sensors to adjust the cutting speed based on material response in real time. When materials are engaged without excessive force, operators can achieve cleaner cuts, enhancing the overall quality and reducing the need for secondary finishing processes. This technique not only preserves material integrity but also contributes to a significant performance boost in CNC operations.

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: [email protected]

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information