Exploring the Top Alternatives to Best CNC Router Machine for Your Manufacturing Needs

As the manufacturing industry continues to evolve, the demand for precision and efficiency has never been more critical. The CNC router machine stands out as a vital tool, offering capabilities that enhance production quality and reduce labor costs. According to recent reports from the Association for Manufacturing Technology, the global CNC machine tool market is projected to reach $100 billion by 2025, reflecting an annual growth rate of approximately 7.7%. However, while CNC routers are invaluable, they are not without their challenges, including high initial investments, maintenance costs, and limitations in material versatility. This article delves into the problems associated with conventional CNC router machines and explores alternative solutions that can cater to varied manufacturing needs, ensuring that businesses can optimize their operations without compromising on quality or efficiency.

Understanding CNC Routers: What Makes Them Essential for Manufacturing

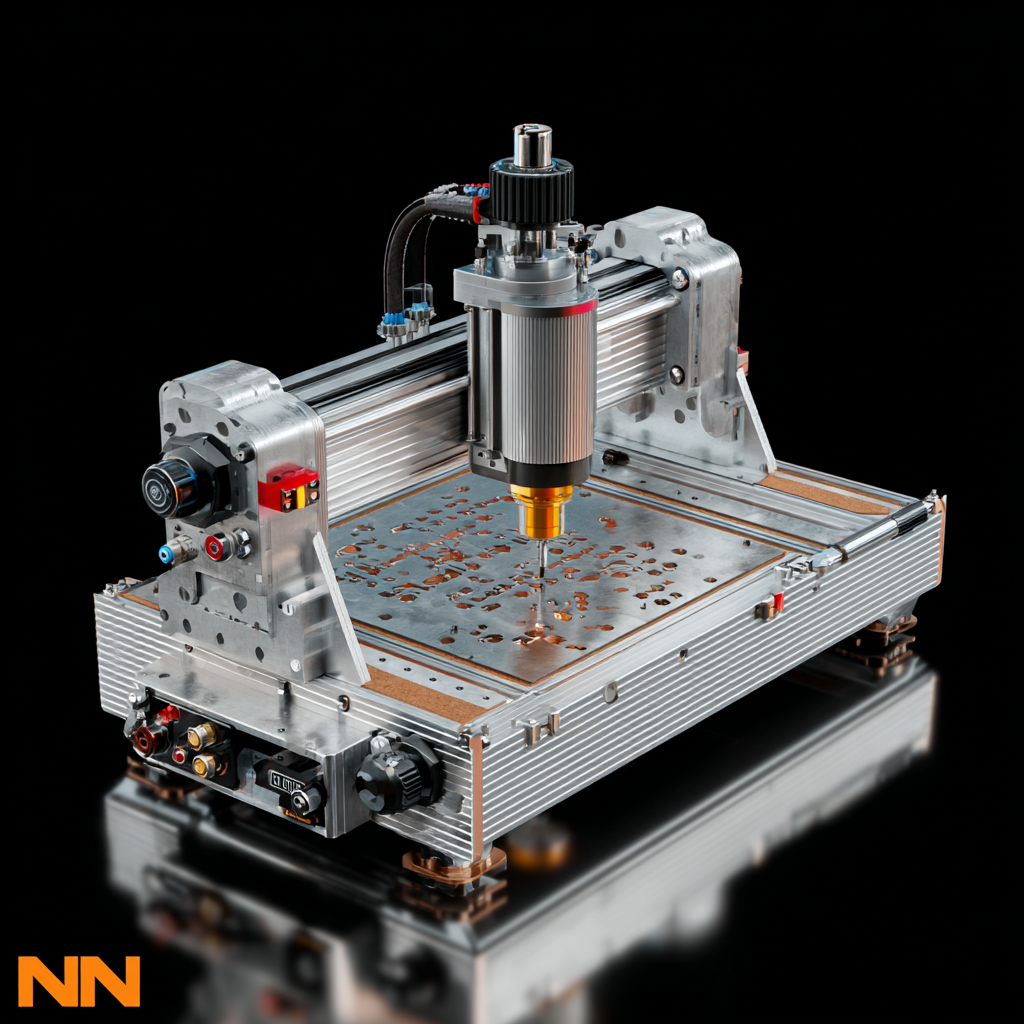

CNC routers have become indispensable tools in modern manufacturing, seamlessly blending precision with automation. These machines employ computer numerical control (CNC) technology, allowing for the meticulous cutting, carving, and shaping of materials across various industries. Their ability to work with wood, metal, plastic, and composite materials makes CNC routers incredibly versatile, catering to diverse manufacturing needs. With their programmable designs, manufacturers can achieve complex shapes and intricate details that would be impossible with manual methods, enhancing production efficiency and craftsmanship.

Understanding the essential features of CNC routers is key to maximizing their potential in manufacturing. Factors such as spindle speed, cutting area size, and the types of compatible tools greatly impact a CNC router's performance. Moreover, the choice between different control systems—like G-code or proprietary software—can influence ease of use and flexibility for various projects. By comprehensively evaluating these attributes, manufacturers can select the best CNC router or explore viable alternatives that align with their specific operational goals. This knowledge empowers businesses to optimize their workflow and expand their creative possibilities in product development.

Top CNC Router Alternatives: Highlighting Features and Benefits

When considering alternatives to the best CNC router machines, manufacturers benefit from exploring a variety of options that can meet different operational needs. Notably, laser engraving machines have gained popularity, providing precision and versatility in material processing. According to a report by MarketsandMarkets, the global laser engraving market is projected to reach $5.65 billion by 2025, growing at a CAGR of 6.2%. The ability of laser machines to handle intricate designs on a range of materials makes them an excellent choice for businesses requiring high detail in their production processes.

Another compelling alternative is the 3D printing technology, which has transformed manufacturing by enabling rapid prototyping and customization. A report from Wohlers Associates states that the 3D printing industry is expected to grow from $12.6 billion in 2020 to more than $35 billion by 2024. This technology allows manufacturers to produce complex parts with minimal waste, thereby enhancing efficiency. Furthermore, the adaptability of 3D printers to various materials, including plastics, metals, and ceramics, offers manufacturers a flexible solution tailored to their specific requirements. Exploring these alternatives not only broadens the scope of capabilities but also fosters innovation and competitiveness in the manufacturing sector.

Top CNC Router Alternatives: Features and Benefits

Comparative Analysis: Popular CNC Router Brands in the Market

The global woodworking machinery market is witnessing significant growth, projected to expand from $5.23 billion in 2025 to $7.88 billion by 2032, with a remarkable compound annual growth rate (CAGR) of 6.0%. This uptrend is driving manufacturers to explore the most effective CNC router machines to enhance their production capabilities. As competition in the market intensifies, identifying the right tools is essential for optimizing manufacturing processes.

In this comparative analysis, several popular CNC router brands are examined, each offering unique features tailored to diverse manufacturing needs. Factors such as precision, speed, and versatility are critical in determining the suitable model for different applications. With advancements in technology, some brands have incorporated innovative software solutions that integrate seamlessly with CNC machines, enabling users to achieve higher efficiency and better outcomes. As the woodworking sector evolves, staying abreast of these options becomes paramount for manufacturers looking to maintain a competitive edge.

Exploring the Top Alternatives to Best CNC Router Machine for Your Manufacturing Needs - Comparative Analysis: Popular CNC Router Brands in the Market

| Feature | Alternative 1 | Alternative 2 | Alternative 3 |

|---|---|---|---|

| Max Working Area (mm) | 1200 x 800 | 1500 x 1000 | 1000 x 600 |

| Spindle Power (kW) | 2.2 | 3.0 | 1.5 |

| Max Speed (mm/min) | 24000 | 30000 | 20000 |

| Precision (mm) | 0.05 | 0.03 | 0.07 |

| Weight (kg) | 300 | 400 | 250 |

| Price (USD) | $2,500 | $3,800 | $1,800 |

Cost-Effective CNC Router Options for Small to Medium Businesses

When exploring cost-effective CNC router options for small to medium businesses, it's essential to consider machines that provide an excellent balance between affordability and performance. For businesses that may not have the budget for high-end models, there are several alternatives that deliver robust functionality without breaking the bank. For example, desktop CNC routers have gained popularity for their compact size and lower price points, making them suitable for smaller workshops. These machines often come equipped with powerful features that can handle various materials, from wood to plastics, making them versatile tools for numerous applications.

Another option worth considering is the entry-level CNC routers that cater specifically to small businesses. These machines typically offer enough horsepower and precision for basic manufacturing needs while remaining budget-friendly. By investing in a reliable yet inexpensive machine, small to medium businesses can increase productivity without the hefty price tag of industrial-grade routers. With the right choice, business owners can achieve high-quality results in their projects, paving the way for growth and expansion in their manufacturing capabilities.

Innovative Technologies Shaping the Future of CNC Routing Machines

The landscape of CNC routing machines is rapidly evolving, driven by innovative technologies that are reshaping the manufacturing industry. As manufacturers look for alternatives to traditional CNC routers, advancements such as automation, artificial intelligence, and machine learning are becoming key players in optimizing production processes. These technologies not only improve efficiency but also enhance precision, allowing for more intricate designs and faster turnaround times.

Moreover, the integration of smart technology into CNC routers is facilitating real-time monitoring and diagnostics. This means that potential issues can be identified and rectified before they escalate, reducing downtime and maintenance costs. Companies that adopt these cutting-edge solutions can expect to see a significant boost in productivity while also enjoying the flexibility to adapt to changing market demands. As the future of CNC routing machines unfolds, embracing these innovative technologies will be essential for manufacturers aiming to stay competitive in an increasingly automated world.

Siemensstraße 13-15

47608 Geldern

NRW Deutschland

Mail: [email protected]

Head office:

+49 (0) 2831 91021-20

Fax:

+49 (0) 2831 91021-99

SUPPORT and INFO

from 3 p.m. to 6 p.m:

+49 (0) 2831 91021-60

( please ring for a long time )

Monday to Friday

8.00 – 12.30

and 13.00 – 15.00

Visit / collection by appointment only!

➣ Sign up for our newsletter

Benefit from a 20% discount, don’t miss any events and always stay up to date.

To access the actual content, click on the button below. Please note that data will be passed on to third-party providers.

More information